Technical parameters

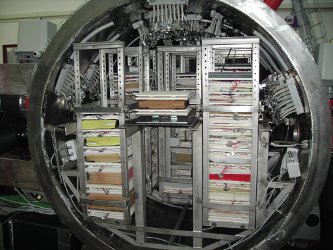

| Overall dimensions | 5600x2000x3000 mm |

| Total weight | 3600 kg |

| Chamber diameter | 1400 mm |

| Chamber length | 1600 mm |

| Chamber volume | 3.12 m3 |

| Power supply | 3x400V/50Hz |

| Maximum input power | 30 kW |

| Operating temperatures | -60 až +65°C |

| Vacuum | |

| Operating pressure abs. | 1 .. 1000 mbar |

| Temperature | -10 .. 60 °C |

| Conditioning | |

| Temperature | -5 .. 70 °C |

| Relative humidity | 20 .. 95 % |

The basic drying procedures which are used in the clever multipurposal drying chamber:

• Vaccum drying: The book or record is dried in the vacuum, but there is supplied by aid of intelligent heating tiles only such a quantity of warmness, which results into the passage of the water in the books from solid state into the liquid one, the water than evaporates under lower temperature which does not cause any degradation of the paper.

• Vacuum freezing – lyophilisation: The books are dried by sublimation of the ice in the vacuum without the passage of the ice into the fluid state. There is supplied into the chamber by aid of heating tiles only such an amount of temperature which cause the transition of the water from the liquid state into the fluent state and which does not increase the temperature of the books above the triple point. This way of the drying is used mainly at the documents, where is a danger of dissolving of the colour pigments, inks, stamp colours, etc.

• Drying in the controlled atmosphere: The books are dried under normal atmospherical pressure, when there is circulating in the chamber the air, or another kind of gas, which is adjusted to the requested temperature and humidity. The usage of a specific gas prevents for example the spreading of the mould in the documents also by higher temperatures. That enables to dry documents practically for an unlimited period without a danger of their degradation. By using of this method are dried documents, which can not be dried with previous methods.

• Disinfection: The books are exposed to the performance of an effective disinfectioning substance. The vacuum eases the penetration of this substance into the interior of a paper of the documents in its full content.

• Acclimatisation (conditioning) of the books: The books are acclimatisated in the drying chamber by air with controlled temperature and relative humidity to the parameters which will be in the spaces of their future storing.

It differs from other dryers by integrating a vacuum chamber with a freezer and conditioning unit with precise temperature and relative humidity control in one machine.

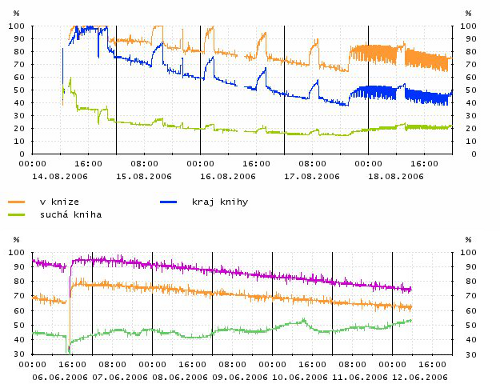

The control system allows the process parameters to be set easily according to the current requirements. The equipment is designed for fully automatic work taking into account the maximum safety of the documents being dried. The data collected during the drying process makes it possible to determine the chemical and physical influence of the drying parameters on the documents so that the gentlest drying process can be selected according to the type of documents.

Another unique feature is the use of independently controlled heating plates, developed specially for this application. Each plate has heating elements, heat-sensing elements and an autonomous controller that maintains the desired temperature on the plate surface.